In recent years, outdoor sports such as mountaineering, skiing, rock climbing, and camping have become popular among the public. Waterproof fabrics are the first line of protection against the alpine climate with significant temperature changes. It can keep the wearer dry and comfortable even in wet conditions.

Applications for Waterproof Fabric include outdoor sports apparel, footwear, bags, military apparel, and protective apparel. According to the statistics of the United States in 2019, it is estimated that the population over the age of 6 goes out nearly 75 times per person; about 20% of the people participate in outdoor activities at least twice a week.

Waterproof fabrics play a vital role so that the wearer can still feel comfortable when they are active outdoors in wet conditions and avoid the cold and wet feeling caused by sweat on the skin. This article will look in-depth at what is a breathable waterproof fabric, how it works, and some of the most popular types today.

Basic knowledge of waterproof and breathable

The common microporous on the market are hydrophobic materials. The material has countless small holes invisible to the naked eye, smaller than water molecules but larger than water vapor molecules. Thus, they can prevent water molecules from entering but allow water vapor molecules to pass through. The hydrophilic glue has no holes to directly block water penetration into the garment, absorbing the moisture emitted by the skin through the hydrophilic material. It then evaporates into the environment.Microporous

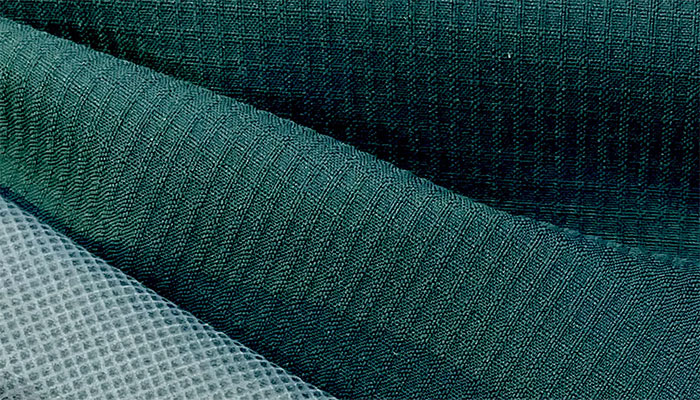

Fabric plus waterproof and permeable layer we call 2 layers, and 2.5 layers will be printed on the back (coating surface or lamination surface) pattern. Of course, you can also do three-dimensional printing to avoid the uncomfortable feeling of the fabric sticking to the skin when sweating. The third layer is to add knit fabric outside the waterproof and breathable layer.

How is a waterproof fabric made?

Waterproof fabrics are made by coating or laminating a fabric with a waterproofing material that prevents water from penetrating the fabric. There are different methods used to create waterproof fabrics, but some of the most common techniques include the following:

Coating

The coating is a process in which liquid glue is applied to a cloth and then cured, and hydrophilic and hydrophobic types are also available. Because it is a coating, the durability of the coating is relatively good, and it is not easy to peel off. It will be harder and stiffer than the lamination cloth, and it is easier to have the sound of clothes rubbing.

After applying liquid to fabrics in the coating process, it needs to undergo curing. There are two methods in the process: wet and dry.

Dry hydrophilic coating and wet micro-porous coating have good waterproofing effects, but the biggest difference is that they are suitable for different testing methods. The dry coating is suitable for the JIS L 1099 B1 cup-inverted method, while the wet coating is suitable for the JIS L 1099 A1 cup-upright method.

In a dry type process, the fabric is immediately dried in a stenter to stretch and dry it simultaneously. In contrast, a wet type process involves exchanging the chemicals in the coating with water in a tank before the fabric enters the stenter for drying.

However, deciding which coating to use will depend on the type of fabric, the end product (jacket or pants, etc.), and the desired effect on the waterproof fabric.

Lamination

Lamination is bonding a waterproof and breathable membrane to the fabric. The lamination process can give the fabric a soft hand feel, maintain the elasticity of the fabric, reduce the noise generated by the friction of the fabric, and provide excellent comfort when wearing clothes.

The membranes used in waterproof fabric for clothing are specialized films that use the size of the pores in the film itself to prevent water molecules from entering while allowing water vapor molecules to pass through, making them waterproof and breathable.

Some membranes use their non-porous and hydrophilic properties to achieve waterproof and moisture-permeable functions.

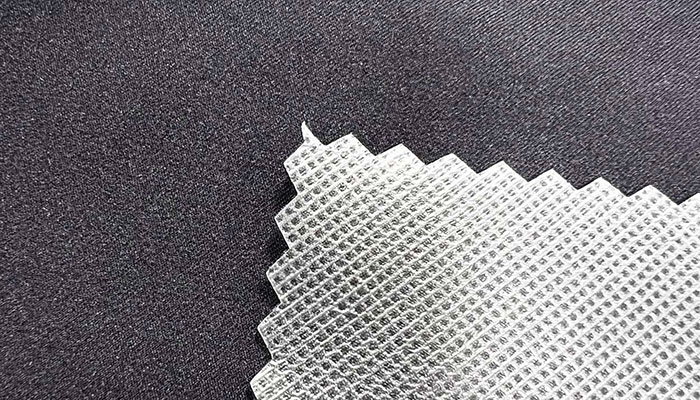

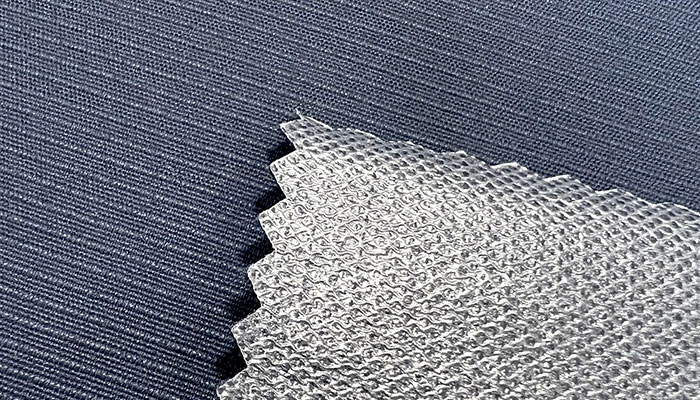

Ultimately, the fabric and film are bonded to get the waterproof fabric through either full lamination or dot lamination.

Full lamination involves uniformly bonding them to one another. This lamination results in a complete and continuous bond between the fabrics, with no air pockets or gaps. Full lamination is commonly used in applications requiring a strong and durable bond, such as heavy-duty outdoor gear and rainwear.

Dot lamination, on the other hand, involves applying the adhesive material in a pattern of dots or lines rather than over the entire surface of the fabric layer. This lamination creates a bond between the two layers of fabric at specific points, leaving gaps or air pockets between the bonded points. Dot lamination results in a more breathable fabric with a softer hand feel.

| Full lamination | Dot lamination | |

|---|---|---|

| Adhesive application | Uniform layer over entire surface | Pattern of dots or lines over fabric surface |

| Bond strength | Strong and durable | Weaker due to gaps or air pockets between bonded points |

| Hand feel | bulky / volume | Softer due to gaps between bonded points |

Differences between Full lamination and Dot lamination

Some solvents used in manufacturing can harm the environment. Therefore, most brands, including Sunny Special, use dot lamination /hot-melt glue (PUR) methods to reduce the possibility of environmental damage from solvent.

In the end, the main difference between coated and laminated fabrics is that coated fabrics involve the application of liquid glue to a cloth and its subsequent curing, resulting in a harder and stiffer material than laminated fabrics. The coating imparts good durability and resistance to peeling. On the other hand, laminated fabrics involve bonding a waterproof and breathable membrane to the fabric. This process yields a fabric with a soft hand feel, preserved fabric elasticity, reduced friction noise, and excellent comfort when worn.

How can you tell if the fabric is waterproof?

Waterproof fabrics are defined by the ability for water penetration. But, to determine if a fabric is waterproof and its resistance level is necessary to apply different tests, for example:

- Water drop test

- Water resistance test

- Hydrostatic head test

- Breathability test

Professional tests such as AATCC127, JIS L1092, ISO811, and the Hydrostatic Pressure Test are also available to obtain water resistance certifications. These tests help to determine the degree of water pressure resistance of waterproof fabrics. Higher water pressure levels during the test generally indicate better waterproofing protection. For example, the waterproof coefficient of some outdoor equipment is 10,000mmH₂O, which means it can withstand a water column of 10,000 millimeters before water begins to penetrate.

How to buy waterproof fabric?

When choosing waterproof fabric, you must consider your needs and ensure it performs well in your intended application. The factors that you should consider are:

- Level of Waterproof

- Fabric breathability

- The durability of the fabric

- Fabric Weight

- Fabric cost

1. Level of Waterproof

The waterproof fabric is measured in terms of its hydrostatic pressure, which is the amount of water pressure the fabric can withstand before it leaks. Generally, the higher the hydrostatic head, the more waterproof the fabric. A highly waterproof fabric may be more important for hiking and climbing in wet or rainy conditions.

2. Fabric breathability

Breathability is the ability of a fabric to allow moisture and vapor to escape, which helps to prevent overheating and discomfort. Highly waterproof fabrics can sometimes be less breathable, so it's important to choose a fabric with a balance between waterproofness and breathability that suits your needs. Choosing a highly breathable fabric for high-intensity activities like running or cycling is important.

3. The durability of the fabric

The fabric's durability refers to its ability to withstand wear over time. A durable fabric will withstand repeated use and exposure to the elements without losing its waterproofness or other properties. Generally, woven fabrics are more tear-resistant than knitted ones. Water-repellent or other functions assisted by chemical dyeing, finishing, and post-processing, such as coating and lamination, will affect the functional performance due to washing. After 20 home laundry cycles, conventional DWR only retains 80% efficiency, but SOLAPEL can maintain 70% efficiency even after 120 home laundry cycles.

4. Fabric Weight

The weight of a fabric is an important factor to consider, especially in applications where weight is a concern, such as backpacking or other outdoor activities. A lightweight waterproof fabric is generally more convenient to carry but may sacrifice some durability or waterproofness.

5. Fabric cost

The cost of fabric is also an important factor to consider, especially if you are working with a budget. Some high-performance fabrics can be expensive, so choosing a fabric that balances performance and cost is important.

For example: if you are a student who likes to trek in summer, the price and water pressure function may be your first choice, and it does not matter if there is no moisture permeability function and heavyweight.

On the other hand, to climb Everest mountain. Water pressure, moisture permeability, and weight are all necessary options; as a result, the clothing will be expensive.

It's important to note that even though people frequently believe that Water Repellent, Water Resistant, and Waterproof are the same, only Waterproof materials are designed to completely prevent water from penetrating through the fabric. While all three are focused on solving the same problem, they have important differences.

Types of Waterproof Material

Earlier, we mentioned that coating and lamination processing methods could make materials waterproof and moisture-resistant, but the effectiveness may vary depending on the type of substrate. Below, we describe some types of waterproof material for clothing.

- PU (Polyurethane)

- TPU (Thermoplastic Polyurethane)

- TPEE (Thermoplastic Polyether Ester Elastomer)

- Nylon & Bio Nylon

PU (Polyurethane)

The most inclusive materials, coatings, and laminations can be used. Water pressure and moisture permeability can also meet relatively high standards, and there is potential to add color to create different appearances.

TPU (Thermoplastic Polyurethane)

Because this material's water pressure and moisture permeability levels are diverse, the quality is stable, and the cost is relatively affordable, it is the most common lamination material.

TPEE (Thermoplastic Polyether Ester Elastomer)

TPEE is a type of polyester with thermoplastic and elastomeric properties, making it a versatile material that is waterproof and moisture-permeable. Because TPEE is a thermoplastic material, it can be melted and reformed multiple times without losing its properties, a valuable property for clothing recycling. Currently, only a few leading environmental protection brands are using it.

Nylon & Bio Nylon

They belong to the same material conducive to garment recycling after being laminated with nylon fabric. And due to the hydrophilic nature of nylon, the moisture permeability function will be better than other materials. It is a relatively new and expensive material.

Choosing the Right Waterproof Fabric for Your Activity

How to choose Waterproof fabric for outdoor sports?

- When commuting in the city, you can choose Waterproof fabric with a waterproof factor of 2,000mm - 5,000mm. It is enough for the temperature difference between day and night and short-term rain.

- Skiing & snowboarding can choose Waterproof fabric with a waterproof factor of 10,000mm or more, which can resist most climates.

- For trekking, you can choose Waterproof fabric with a waterproof coefficient of 20,000mm or more. A waterproof jacket of this level is relatively advanced and can withstand various external factors. It is relatively reliable in harsh weather. Of course, prices will also be relatively high compared to the previous two.

Caring for Waterproof Fabric

After participating in outdoor sports, the coat is typically covered with sweat, dirt, and other debris. It's essential to take proper care of the garment. All waterproof and moisture-permeable coats should be kept dry when not in use to minimize any loss of functionality.

Here are some tips for cleaning your waterproof gear and clothing to help it last for years:

- Instead of dry cleaning, try using a low-speed washing machine.

- Use a neutral laundry detergent and avoid adding fabric softener, bleach, or stain remover.

- When drying your coat, follow the label's recommendations to avoid high temperatures or ironing.

By taking these simple steps, you can keep your coat in top shape and ensure that it continues to provide reliable protection from the elements.

Conclusion

After learning about waterproof fabric, if you want to enjoy the balance of waterproof and moisture permeability, most of the products in the outdoor products market are coating and lamination. They have the same waterproof and moisture function, but the grades they can achieve are different.

Coating processing is cheaper and quicker, while lamination is more expensive. Compared with coating, it is also more extensible, and the elastic fabric can increase comfort during activities.

Waterproof fabric is a versatile and important material with many practical applications in our daily life. Whether you're an avid hiker or want to stay dry in wet weather, there's a waterproof fabric. By understanding the different types of waterproof fabrics and how they work, you can choose gear and clothing to protect you from the elements.

You may also like