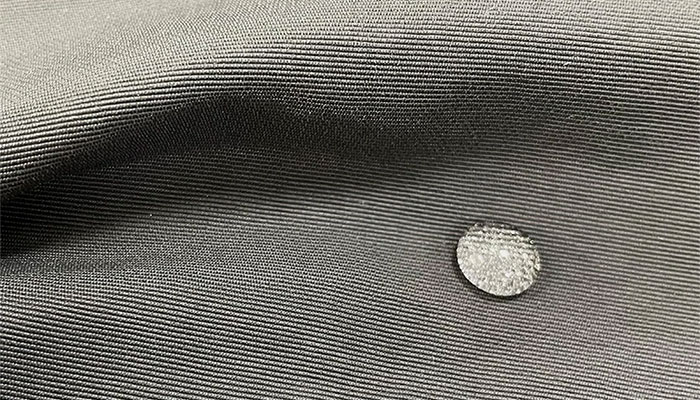

Waterproof coatings are a type of finish applied to fabrics to make them resistant to water. These coatings can be applied to various fabrics, including outdoor gear, clothing, and accessories. All waterproof coatings need to add DWR to improve the effect.

But what is Durable Water Repellent? Durable Water Repellent, aka DWR, is a treatment applied to the outer surface of fabrics to keep them dry quickly.

How does DWR work?

It creates a barrier on the fabric's surface that causes water to bead up and roll off rather than soaking into the fabric. This barrier is the product of applying a coating of chemicals to the fabric.

Only fabrics that have undergone waterproof coating or lamination can be advertised as resistant to water pressure because they have a barrier against water penetration. Therefore, splashing water does not mean waterproofing.

How is DWR apply to jackets?

One standard method for applying DWR to jackets is applying the treatment during manufacturing. This ensures that the treatment is evenly distributed across the jacket's entire surface and provides a durable and long-lasting barrier against water.

Another way to apply DWR to a jacket is by spray-on treatment. These treatments can be applied to finished garments and are typically easy to apply at home. DWR spray can provide a temporary boost to the jacket's water-resistant properties, but they may not be as durable as coatings that are applied during the manufacturing process.

What is their typical durability?

Each brand defines its durability of DWR but usually ranges from 3 to 20 times washing. Currently, most outdoor sports brands will define their DWR at 80/20, which means after 20 times of washing can still have 80% efficiency.

What are the advantages of DWR?

One of the critical advantages of DWR is that it is durable, meaning that it can withstand repeated washings and maintain its water-repellent properties. As a result, the fabric is ideal for clothing and gear subjected to a lot of wear and tear.

What is PFAS?

One of the biggest issues related to DWR is the use of substances called per- and polyfluoroalkyl substances (PFAS), such as C8 or the recent versions of short-chain as C6 and C4, which have substances known to have harmful effects on human health and the environment. As a result, there has been a movement in the textile industry to develop new DWR treatments that are free of PFAS.

In conclusion, Durable Water Repellent is a treatment applied to the outer surface of fabrics to make them resistant to water. It creates a barrier on the fabric's surface that causes water to bead up and roll off rather than soaking into the fabric. DWR can be applied to jackets during the manufacturing process or through spray-on treatment, and its durability typically ranges from 20 items of washing in outdoor apparel.

Overall, DWR is useful for making fabrics water-repellent, but it is vital to consider the potential environmental impacts when choosing a DWR treatment.

- Tags: DWR, SOLAPEL, Waterproof Fabric

You may also like